1 Standard

Q/HNTD 026-2025 Intelligent warning power cable with a rated voltage of 0.6/1kV and below

2 Product Application

Suitable for fixed installation in power transmission and distribution lines with a rated voltage of 0.6/1kV or below, mainly used for power transmission, with temperature monitoring and intelligent alarm functions.

3 Fiber Optic Intelligent Warning Function Description

The intelligent warning cable adds a temperature measurement optical fiber unit on the basis of cable technology. It contains single-mode or multi-mode optical fiber and can be used mainly to monitor the temperature changes of the cable conductor itself and terminal electrical appliances during long-term operation. The pulse signal of the optical fiber can accurately determine the high-temperature location, which can effectively extend the service life of the cable and electrical appliances and is an effective means to prevent electrical fires.

Principle of Intelligent Warning:

Optical fiber acts as a sensor: When laser pulses propagate through optical fiber, three types of scattered light are generated due to the physical interaction between the laser and the molecular structure of the fiber: Rayleigh scattering, Raman scattering, and Brillouin scattering. Among these, Rayleigh scattering is insensitive to temperature, while Raman scattering and Brillouin scattering are both temperature-sensitive, making them suitable for temperature measurement. Additionally, Brillouin scattering is highly sensitive to stress and can detect changes in surrounding stress conditions. Since Brillouin scattering and Rayleigh scattering are very close in the spectrum and difficult to distinguish, and Brillouin scattering is also significantly influenced by stress and other factors, it is challenging to use for temperature measurement. Currently, the most technically mature approach is to use Raman scattering-based distributed fiber optic temperature sensors.

Principle of Distributed Fiber Optic Temperature Measurement: A distributed fiber optic temperature measurement system is a real-time, rapid, multi-point temperature measurement and spatial temperature field distribution sensing system. It is a distributed, continuous, functional fiber optic temperature measurement system, where the fiber optic cable serves not only as a sensing unit but also as a transmission unit within the system. The system primarily utilizes two principles—Raman scattering or Brillouin scattering and Rayleigh scattering—to achieve temperature measurement and localization functions: by leveraging the temperature effect of backward Raman scattering or Brillouin scattering in the fiber optic cable, the temperature field where the fiber optic cable is located can be measured in real time; by utilizing Rayleigh scattering (Optical Time Domain Reflectometer (OTDR)), fiber optic attenuation can be measured, and the measurement point can be precisely localized.

Principle of Optical Time Domain Reflectometer (Location Information): When the pulse light signal emitted by the laser is transmitted through the optical fiber, the backscattered light generated at different positions reaches the detector at different times. The time difference between the arrival of the backscattered light at the detector and the emission of the light pulse by the laser is multiplied by the speed of light in the optical fiber and then divided by 2 to obtain the location of the scattering point on the optical fiber.

4 Features

4.1 Cable Rated Voltage

U0/U: 0.6/1 kV

4.2 The maximum rated operating temperature of the cable conductor is 90℃.

During a short circuit, the maximum temperature of the cable conductor is 250℃, with a duration not exceeding 5 seconds.

4.3 Installation Ambient Temperature

The Ambient temperature during cable installation should not be lower than 0℃; otherwise, preheating is required.

4.4 Bending Radius

The minimum bending radius during cable installation: 20D for single-core unarmored cables, 15D for multi-core unarmored cables, 15D for single-core armored cables, and 12D for multi-core armored cables, where D is the cable outer diameter.

4.5 Fiber Optic Transmission Performance

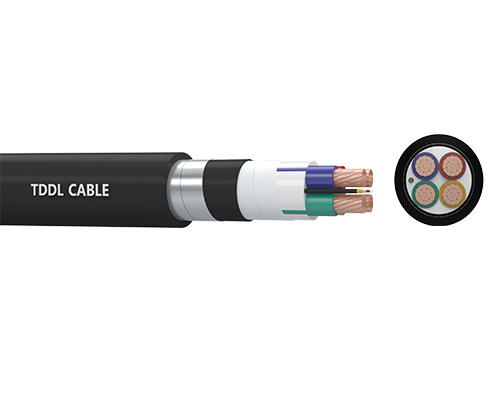

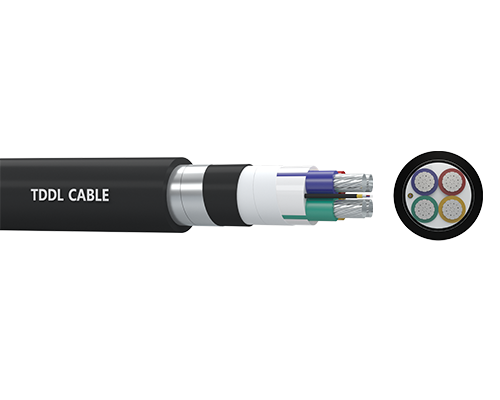

5 Structural Diagram

5 Transportation and Storage

5.1 Before transporting or rolling cable drums, ensure that the cable drums are secured and the cables are tightly wound. When rolling, follow the arrow on the cable drum or the direction of the cable’s winding.

5.2 During transportation, cable drums must be placed securely and fixed using appropriate methods to prevent collisions or overturning, and must not be damaged. Cable drums must not be transported or stored in a horizontal position.

5.3 It is strictly prohibited to push cable drums directly off the transport vehicle.

5.4 When loading or unloading cable drums, it is strictly prohibited to lift multiple drums simultaneously.

5.5 Cables should be stored in a centralized and categorized manner, with clear markings indicating the model, voltage, specifications, and length. The storage area for cables should not have standing water.

5.6 During storage, the cable drums and packaging should remain intact, with complete markings and securely sealed ends. Any defects should be addressed promptly.

.png)

.png)

.png)